Product Implementation Service

Production Planning & Process Mapping

Analysis of customer requirements and mapping of the technology, the materials, and the processes.

Quality Assurance

Procedures

Defining the incoming, in-process, and final inspection criteria, quality levels, sampling plans, and check points.

We ensure that quality is an integral part at every stage of our services and in delivering your parts/products. We follow a simple but strict principle of PDCA (Plan Do, Check & Act).

Our Quality Assurance defines the processes; quality standards and processes used, training, quality auditing, sampling plans, testing, and Quality Control, comprising of control of incoming data, materials and parts, in process control, final control – delivery inspections.

Production Pilot Testing & Validation

Validation of the products through the complete production process on a small scale, process adjustments, and timing checks.

Optimization & Nesting for Production

Adjustments of production build nesting based on the production pilot run results.

Test & Validation Production

Build

Final test and validation build, and review of direct the material and production costs per pilot build.

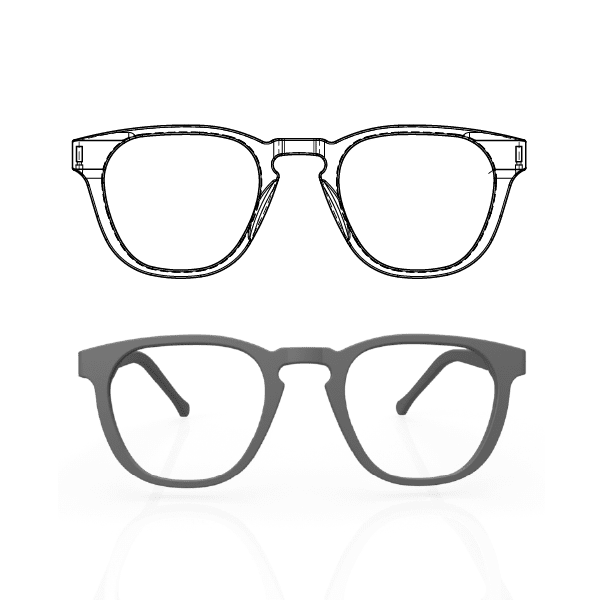

Product Development & Implementation

Add On Services

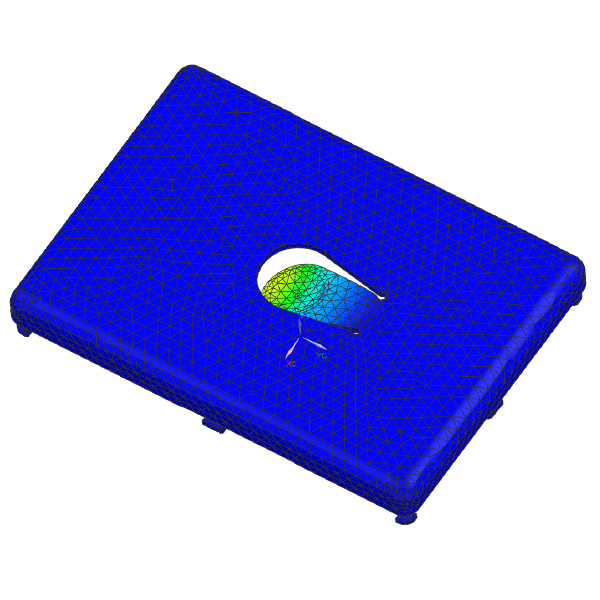

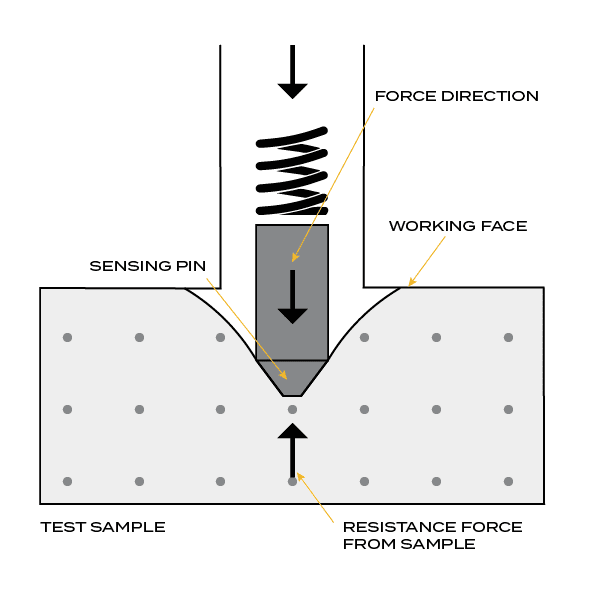

DEFLECTION ANALYSIS

Simulations by applying required force over the specific areas on the 3D model to analyze the deflection of material within the 3D environment.

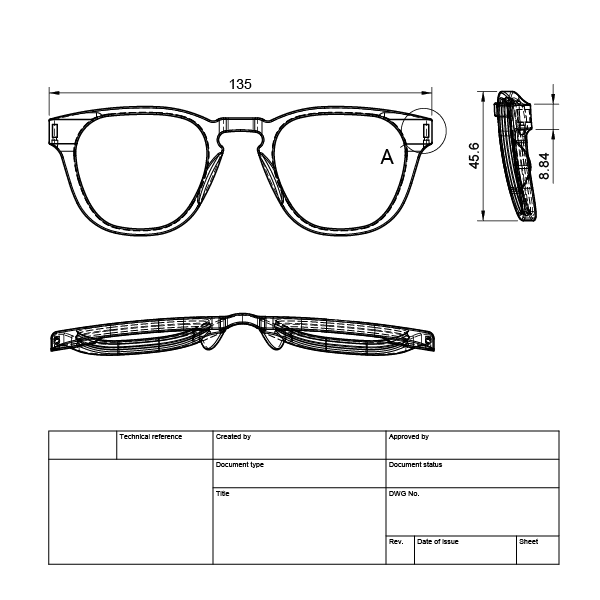

TECHNICAL DRAWINGS

Conversion of the 3D model into three main 2D views, adding overall and critical dimensions, including tolerances.