More than a shoe - it’s a new manufacturing model built for people and the planet.

A step toward a future where production is local, personal, and circular.

The new familiar

3D printed shoes usually look like they belong in a museum, not on the street. They prioritise the process over the product.

METIS is a revolutionary model made with 3D printing, not for it. We stripped away the bulky, futuristic designs usually associated with this technology. In their place we focused on clean lines, modern style, and invisible innovation. This is technology that doesn’t need to be shouted about - it simply needs to be quietly embraced.

More than a shoe-shaped object

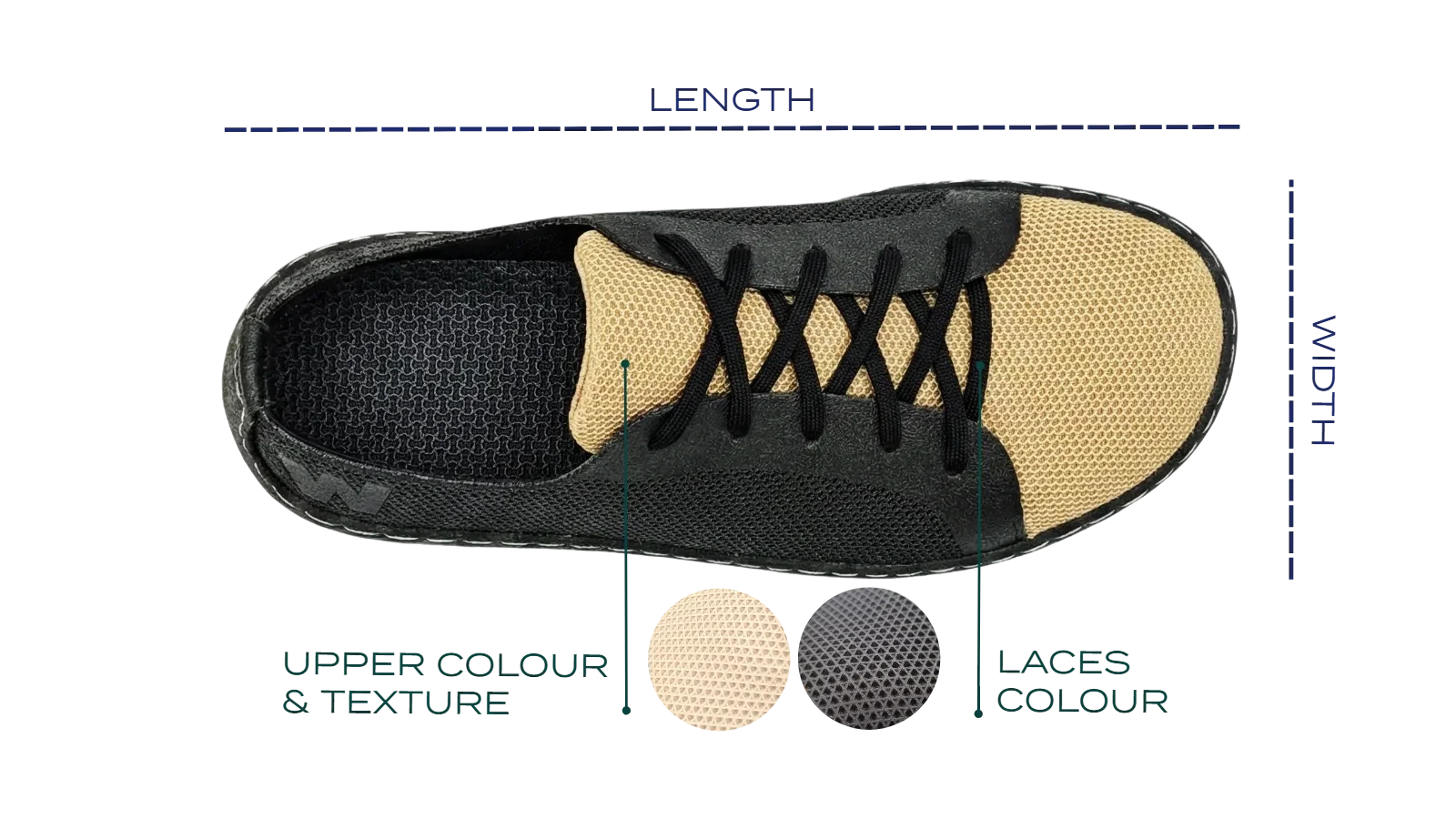

METIS is made for real people. Traditional manufacturing relies on standard sizes that fit almost no one perfectly. METIS moves beyond the limitations of the "average" foot.

By taking simple measurements, we precisely adapt the shoe’s geometry to the unique parameters of the wearer - creating a wide, anatomical fit that respects natural movement. It is a production model that honors the person first, printing the perfect pair only when it is asked for.

Made to be unmade

METIS delivers the classic look of a daily sneaker, but with a radically cleaner footprint. The industry standard is to fuse materials with chemical adhesives, making separation - and therefore recycling - nearly impossible.

We took a different path. Using our own EasyStitch© technology, we construct the shoe without a single drop of glue. This creates a durable bond for the wearer, yet allows for simple disassembly at the end of the lifecycle. It is a system designed for zero waste.

Anatomy of METIS

A smart system that integrates seamlessly with human biomechanics, offering a precise fit for the wearer and a flexible canvas for your brand.

Looking for a sustainable, custom-branded manufacturing solution?

The METIS platform is now open for collaboration. We enable forward-thinking brands to use our modular architecture as the foundation for their own footwear collections.

To learn how METIS can power your next product line, leave your email below and our team will be in touch shortly.

METIS is just the beginning…

New designs coming soon

WAZP has been selected to exhibit our METIS Footwear solution at ChangeNOW Summit 2026 in Paris!

Contact us to meet at the Grand Palais in Paris on March 30 - Apr 1