Printing & Finishing Services

By taking full advantage of our Distributed Manufacturing Footprint and Certified Partner Network you can trust us to take care of all the planning and management of your 3D Printing production and manufacture products and parts to your specification, every time.

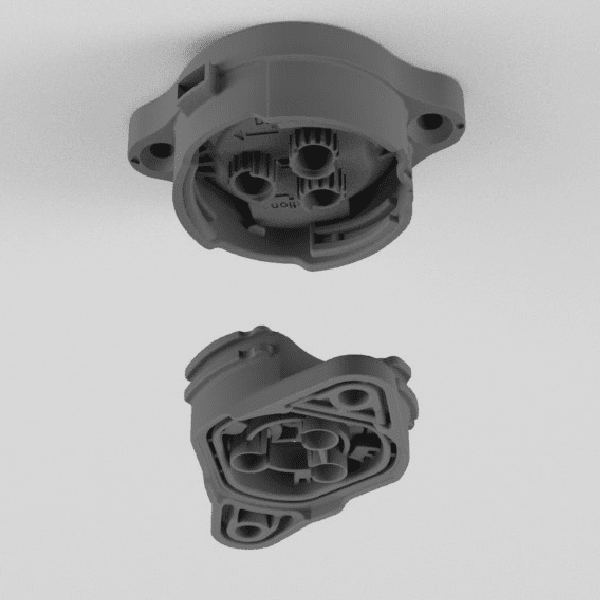

Printing

Using 3D printers as one of the tools in the production process and supply chain, we produce highly complex, and functional parts and products. The technology works on the principle of building up the parts or products layer by layer as an additive process (effectively growing them), compared to mainly subtractive processes in traditional manufacturing. By using 3D printing we are much faster, with much less waste, and more cost-effective than traditional manufacturing.

Blasting

The blasting process is a post-process step we use in preparing the parts or products for the finishing processes after 3D printing. The technique is similar to sandblasting, however in our case we use variations of glass beads or other blasting media. The type of blasting media combined with blasting pressure depends on the functional and mechanical properties of the parts or products, the material, and the down-line finishing requirements.

Surface Smoothing

We use surface smoothing and polishing technologies, including standard technology (tumblers) and/or our proprietary techniques to achieve a specified surface texture, and finish. The Surface Roughness (Ra) and Surface Gloss (Ga) is dependent on the parts or product's final specifications and our customers' requirements.

Surface Dyeing

For parts and products produced using Selective Laser Sintering (SLS) and the following materials PA12, PA11, and TPU we can finish them using dyeing technology. We use environmentally friendly dyes and can dye the items in a range of RAL and/or Pantone colours.

Surface Coating

When finishing with Coatings we use water-borne coatings that are environmentally friendly. We can provide finishes in the full range of RAL and/or Pantone colour systems. Ranging from matte, glossy, clear, and metallic surface colours, and Surface Gloss (Ga) depending on your requirements.

WAZP is a digital end-to-end supply chain solution with a distributed manufacturing footprint empowering us to offer our clients easy and smart access to volumes and production facilities for fast and flexible manufacturing.

By producing close to the point of need we can offer Tailored Logistics Solutions that suit your needs and minimize your product’s footprint. Distributed Manufacturing enables Localized Production, or production close to the point of need which has a major impact on logistics, reducing cost and lead times.

Furthermore, Just In Time or On-Demand Manufacturing enables companies to decrease the need for stock, slashing transportation and storage costs, as well as having a positive impact on the landed cost of goods. We apply a “no-waste” approach to every step in our process and our solution drives the production and delivery of products with accurate, precise and lean “what-when-where” solution.

Manufacture In Multiple Locations – Delivering Close To The Point Of Need

The most efficient, sustainable solution that delivers tangible supply chain benefits of Additive Manufacture by:

- Manufacturing Products Close to End Consumers

- Volume Production Efficiency

- Reducing Transportation, Storage & Other Associated Logistics Costs

- Reduced Time to Market & Delivery Times

- Positively Impacts Carbon Footprint of Products

- Reduces Cross Border Tariffs & Taxes

- Impacts Country of Origin of Products

- Allows Effective Market Adaptation of Products