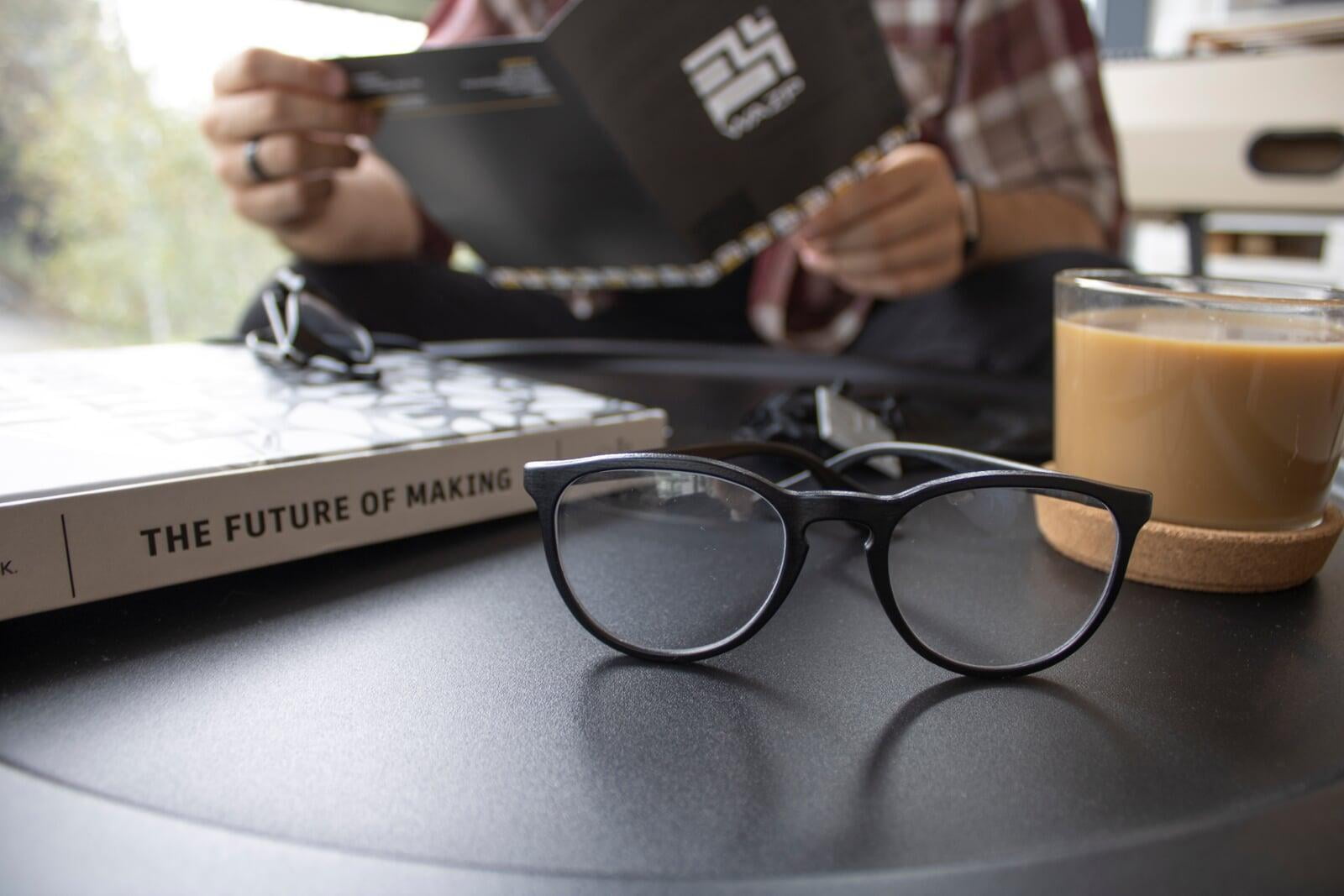

A Fusion of Design & Technology

EXPERTLY DESIGNED

WAZP Eyewear is brought to life by our in-house designers with expertise in designing Eyewear for Additive Manufacturing, creating beautifully crafted, lightweight frames.

SKILLFULLY ENGINEERED

The frames are engineered for precision, optimum quality and comfort ensuring a balanced design.

Its A Sustainable Vision

Sustainability is built into the WAZP DNA by doing more with less, propelling operational excellence through a no-waste culture within the business. We achieve this goal by being creative, efficient and resourceful. Not only does this mean less waste, but it also means increased efficiency at all stages in the supply chain for our clients.

We have successfully reduced material production waste to 2% without compromising the high-quality of our prints. By leveraging the power of our supply chain solution, we are reducing our carbon footprint by manufacturing products close to the point of need.

The Eyewear Industry takes 70 Supply Chain steps, WAZP can do it in less than 10!

What to do next?

01

SPEAK WITH OUR TEAM ABOUT MANUFACTURING

We are working with leading brands in the Eyewear Industry. See how you too can take advantage of WAZP’s Global Supply Chain for AM.

02

REQUEST AN EYEWEAR

SAMPLE PACK

On request, we would be happy to print and send samples of our Eyewear Frames for you! Simply submit the form and our representative will be in touch.

03

EXPLORE WAZP'S OWN DESIGN LIBRARY

Explore over 50 combinations of frames, designed and manufactured in accordance with EN ISO 12870, ANSI Z80.5 and AUS/NZS 12870 standards.