What are you looking to achieve?

We are the trusted partners to help businesses accelerate their journey to Additive Manufacturing through impartial knowledge transfer, pragmatic development & re-engineering of products for 3D printing, and an expert, result-focused team selected specifically to meet your needs.

MAINTAIN BUSINESS CONTINUITY

IMPROVE BUSINESS RESILIENCY

ACCESS NEW MARKETS

ENHANCE CUSTOMER EXPERIENCES

ACCELERATE PRODUCT DEVELOPMENT

OPTIMIZE SUPPLY CHAIN RELIABILITY

Project Scoping & Planning

We offer complimentary consultancy to all our product development and production clients. To kick start you project and understand the feasibility of Additive Manufacturing for you, simply book a Consultation Call at a time that suits you and our team will support you from the very start of your journey!

Discovery Workshop

Customer workshop with the Project Lead to identify requirements, challenges, and goals for the project.

Project Scope & Brief

Identification of project scope and product brief, and other necessary requirements critical to project success.

Product Range Feasibility Analysis

Analysis of the client’s product range for the suitability and value in production using Additive Manufacturing.

Product Development Service

Our Product Development Service ensures we work closely together to co-create end-use products that meet the quality standards and tight production deadlines, by capturing your customer knowledge and our Design for Additive Manufacturing (DFAM) expertise. Together, we manage the entire process – from concept development to market-ready prototypes of your product.

Product Requirements Review & Analysis

Review and in-depth analysis of product and project requirements, solutions idea generation, and the development of a detailed project plan.

Project Management, Briefing & Co-Ordination

The internal project team and external client meetings, progress updates and follow-ups on the project.

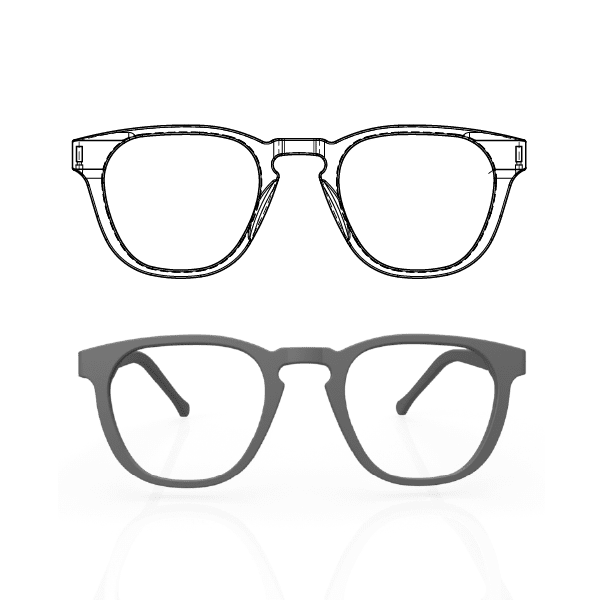

3D Modelling – Development

Development and 3D Modelling of a new product based on customer requirements.

3D Modelling – File Optimization

Existing product file optimization. A full review of the product to eliminate file errors, overlapping surfaces, ensure correct file resolution, apply hollowing as required, and correct orientation for consistent print quality.

3D Modelling – Product Adaptation & Re-Engineering

Existing product re-engineering or adaptation for 3D Printing production.

Prototype Testing & Validation

Rapid prototyping and validation of design to ensure functionality, strength & appearance of the printed sample against the customer requirements.

Orientation Optimization

Orient the product within the production build based on customer requirements to achieve desired appearance, strength, and accuracy.

Nesting Optimization

Nest the products within the production build area to achieve the maximum output.

Design Production Build

Printing of product prototypes to fully validate the parts.

Product Development & Implementation

Add On Services

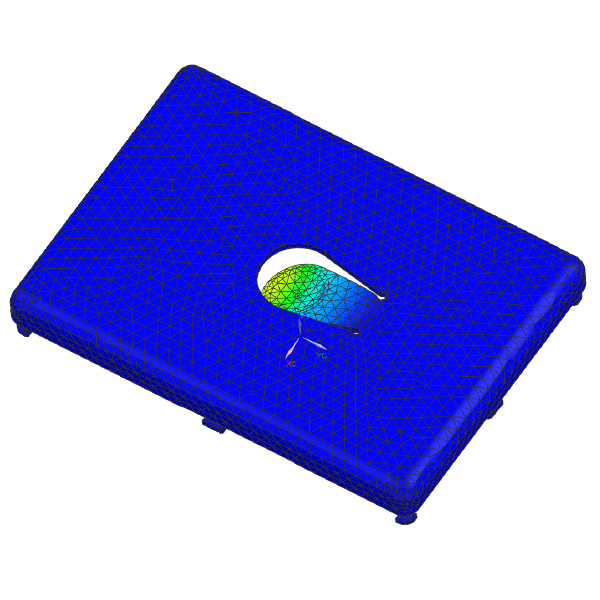

DEFLECTION ANALYSIS

Simulations by applying required force over the specific areas on the 3D model to analyze the deflection of material within the 3D environment.

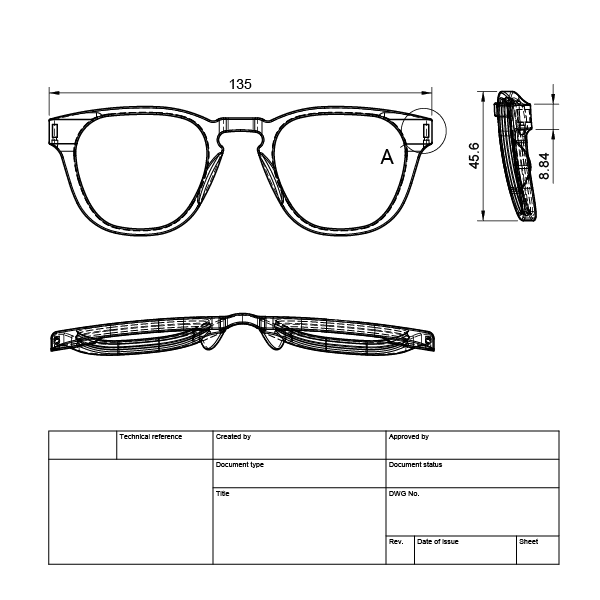

TECHNICAL DRAWINGS

Conversion of the 3D model into three main 2D views, adding overall and critical dimensions, including tolerances.

Why WAZP?

01

PRAGMATIC APPROACH

We work with both suppliers and customers across a wide range of industries, so we understand the challenges and capabilities for both sides.

02

IMPARTIAL TECHNOLOGY KNOWLEDGE

The technology and the solutions we offer to our clients are based on their performance and application for volume production.

03

RESULT-FOCUSED CO-CREATION

We strive for collaborative development with our clients to create new or improved solutions and bring value for the end consumer.

Bespoke 3D Modelling Services

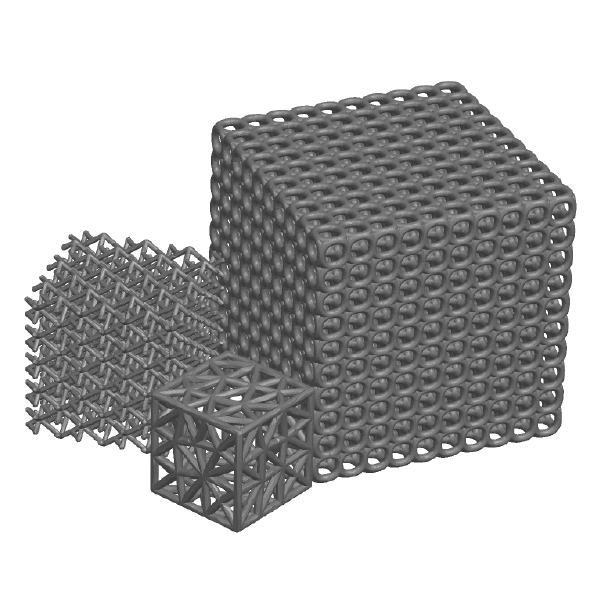

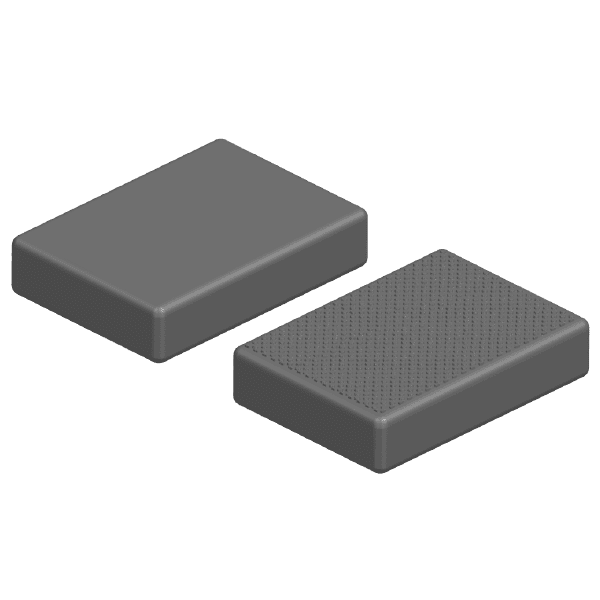

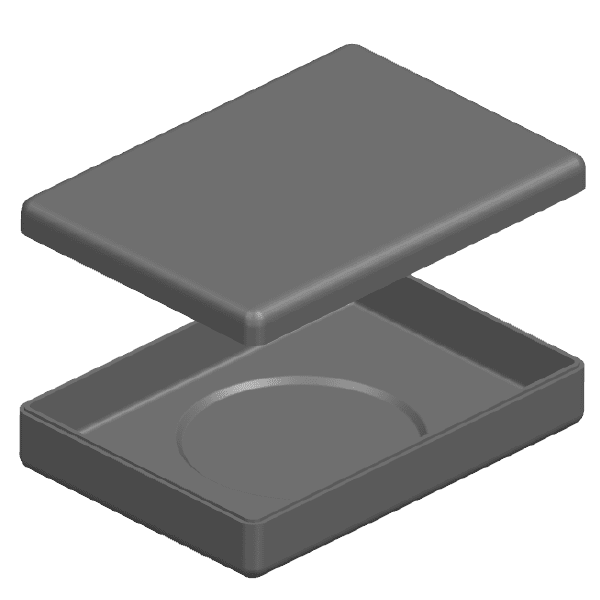

LATTICE & MESH APPLICATION

Application of custom made lattice structures and meshes to achieve reduced product weight, increased strength, improved appearance, and enhanced cost efficiency.

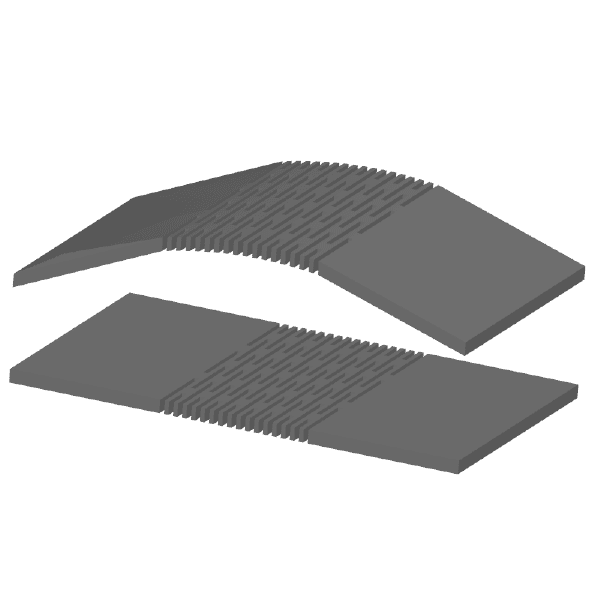

SHAPE BENDING

Bending of the entire 3D model or specific parts of the model to achieve a desired product/part shape based on the customer specified requirements, while maintaining product functionality and integrity.

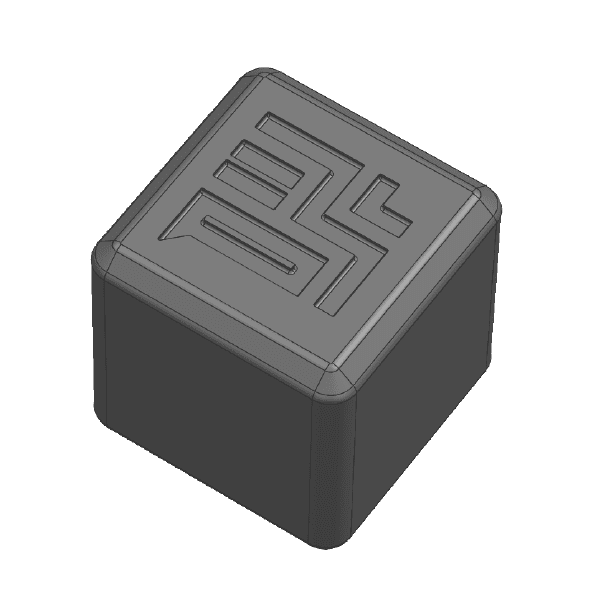

LOGO APPLICATION

Application of brand logo or logotype to the 3D model surface and adapting it to print technology requirements, ensuring brand accuracy.

TEXT APPLICATION

Application of text to the 3D model surface and adapting it to print technology requirements, ensuring legibility and detail.

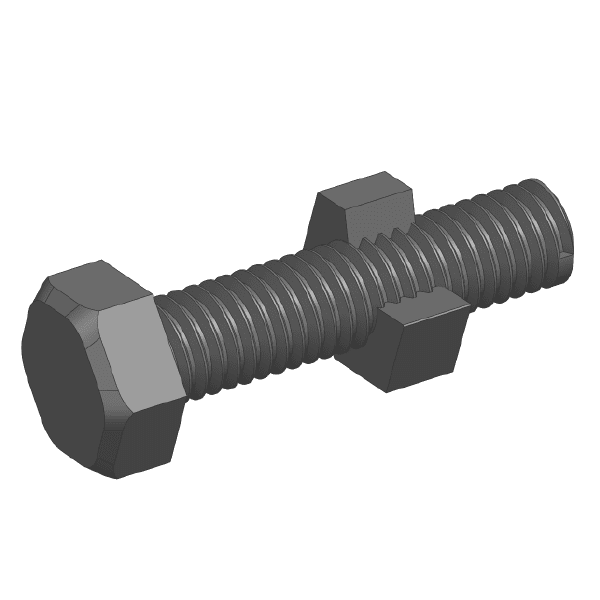

THREADING

Custom development or adaptation of existing threading solutions to achieve strength, durability and reduction in assembly requirements.

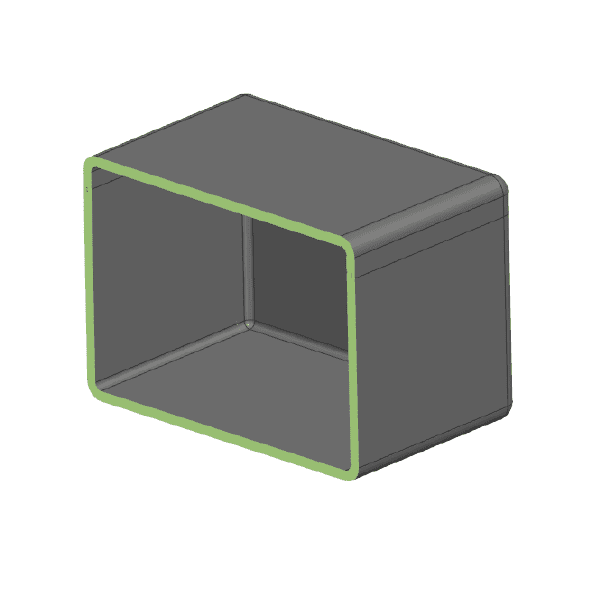

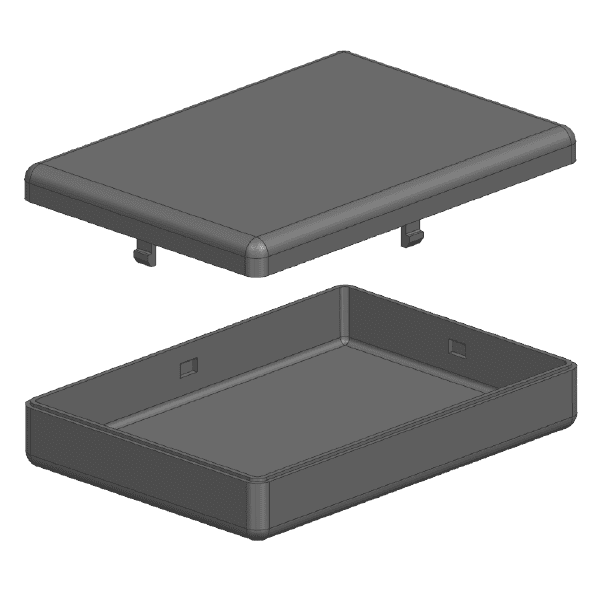

LOCKING/CLIPPING MECHANISMS

Custom design and modelling of locking and clipping mechanisms for a range of industries based on specific customer requirements.