Your Design & Production Guide for Industrial 3D Printing

Adopting new technologies and processes is scary but to ensure a sustainable competitive advantage and growth this is an everyday reality for companies and their dedicated teams.

At WAZP, we specialize in industrial 3D Printing of consumer and industrial products, sustainability driven distributed manufacturing and repetitive quality at volume.

With over 20 years in the manufacturing industry, we are proud to say we are still learning, and as we do we share our knowledge with you!

Chapter 01: AM Technologies & Materials

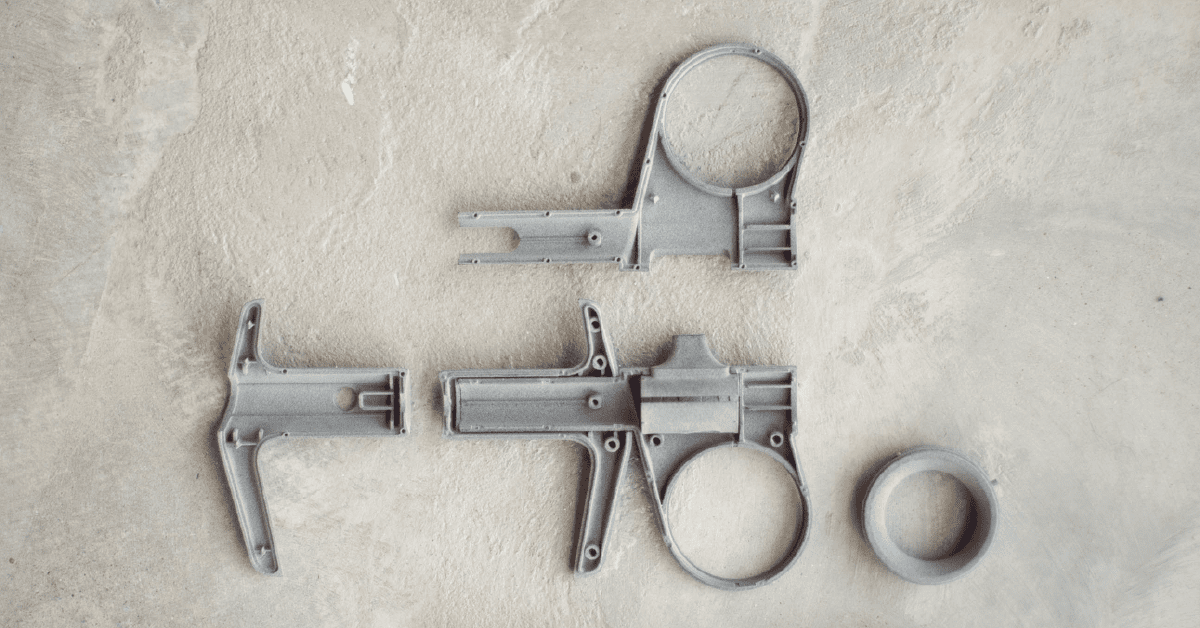

Multi Jet Fusion (MJF)

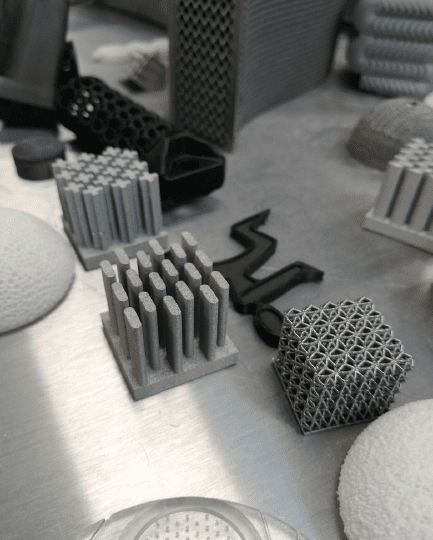

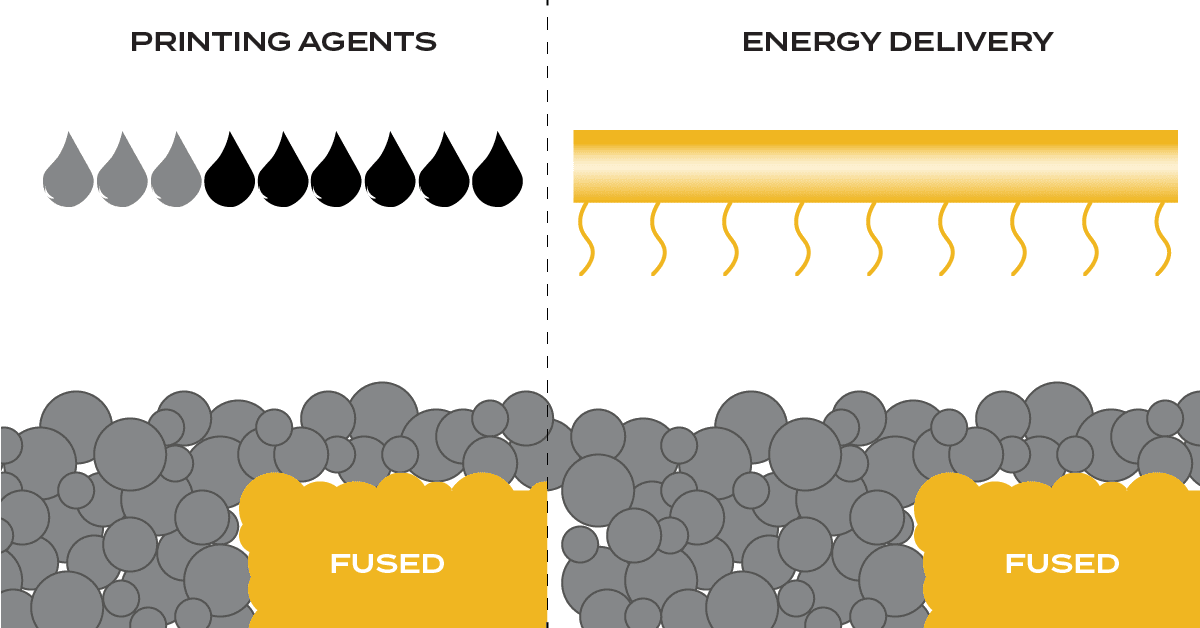

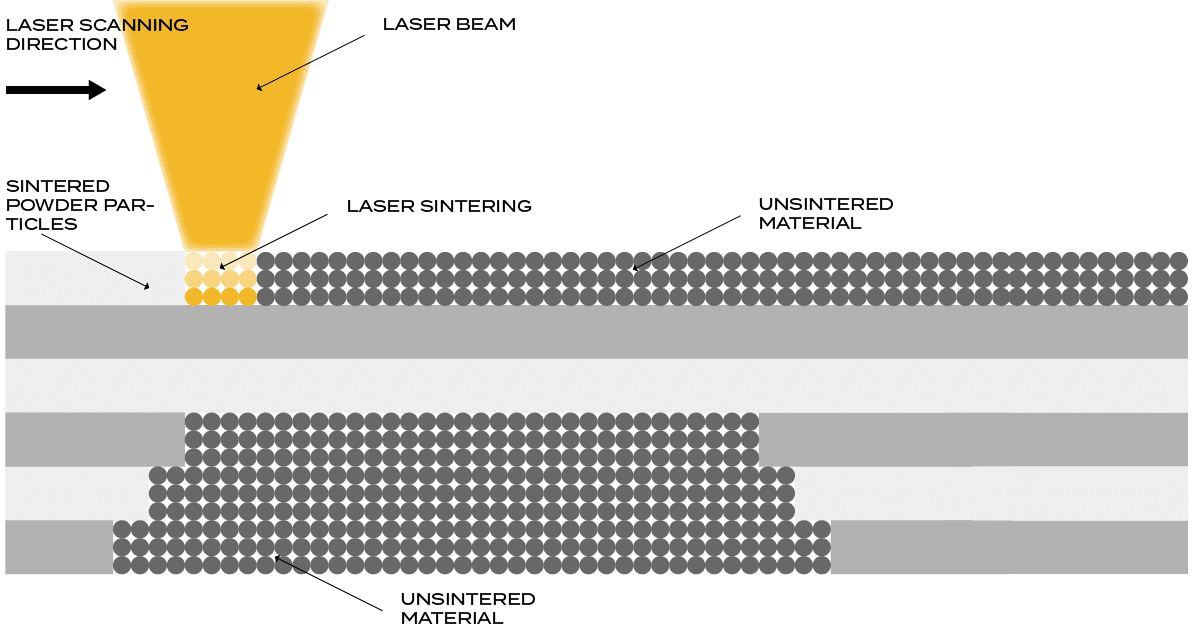

Multi Jet Fusion (MJF) technology is a powder-bed fusion AM technology that allows for the production of accurate, functional products and parts.

Nylon 12 (PA-12) Material Characteristics

PA-12 Nylon is exceptionally strong even when temperatures fall below freezing. It is characterized by being a strong, rigid material that is resistant to cracking with excellent long-term performance.

Chapter 02: AM Post Processing Techniques

Blasting

The blasting process is a post-process step used in preparing the parts or products for the finishing processes after 3D printing.

Surface Smoothing & Polishing

The standard technology used for surface smoothing and polishing is tumblers, which achieve a specified surface texture, and finish.

Chapter 03: AM Applications By Industry

Consumer Electronics

Discover how 3D Printing is used in the Consumer Electronics Industry to develop products, parts and bring value to the end consumer.

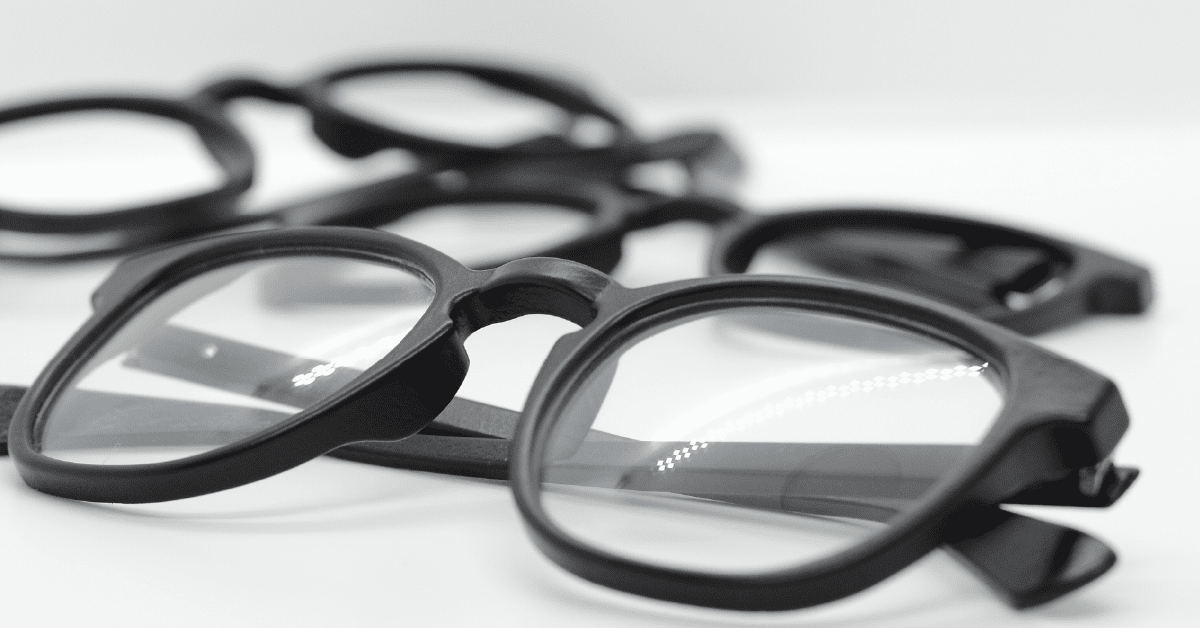

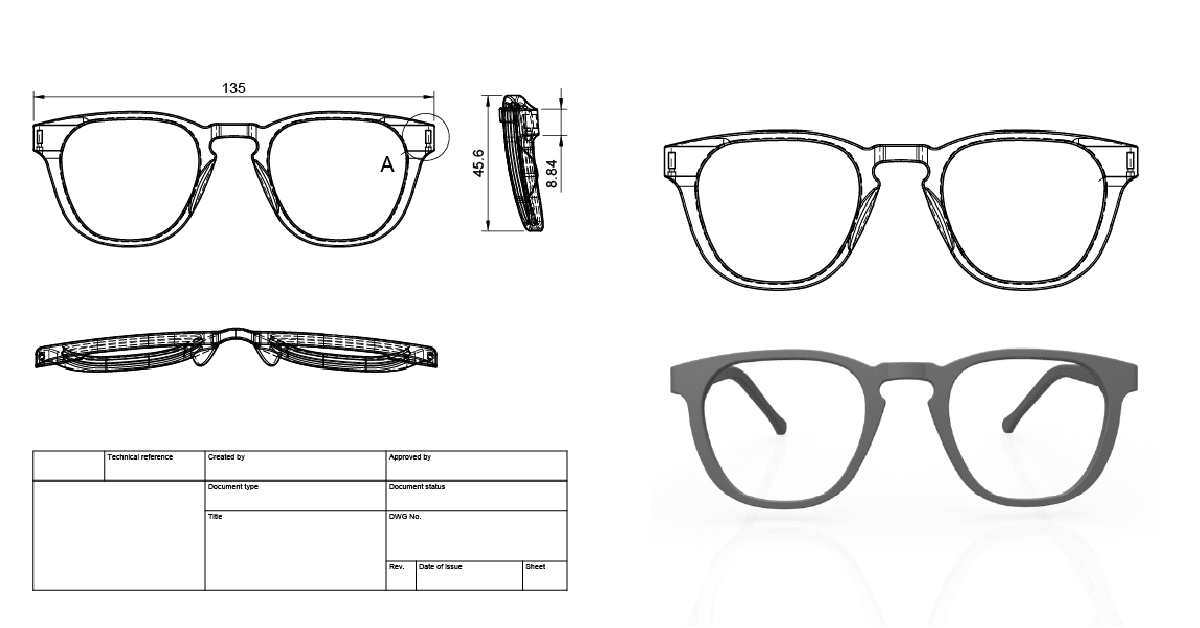

Eyewear

Discover how 3D Printing is used in the Eyewear Industry to develop frames and bring value to the end consumer.

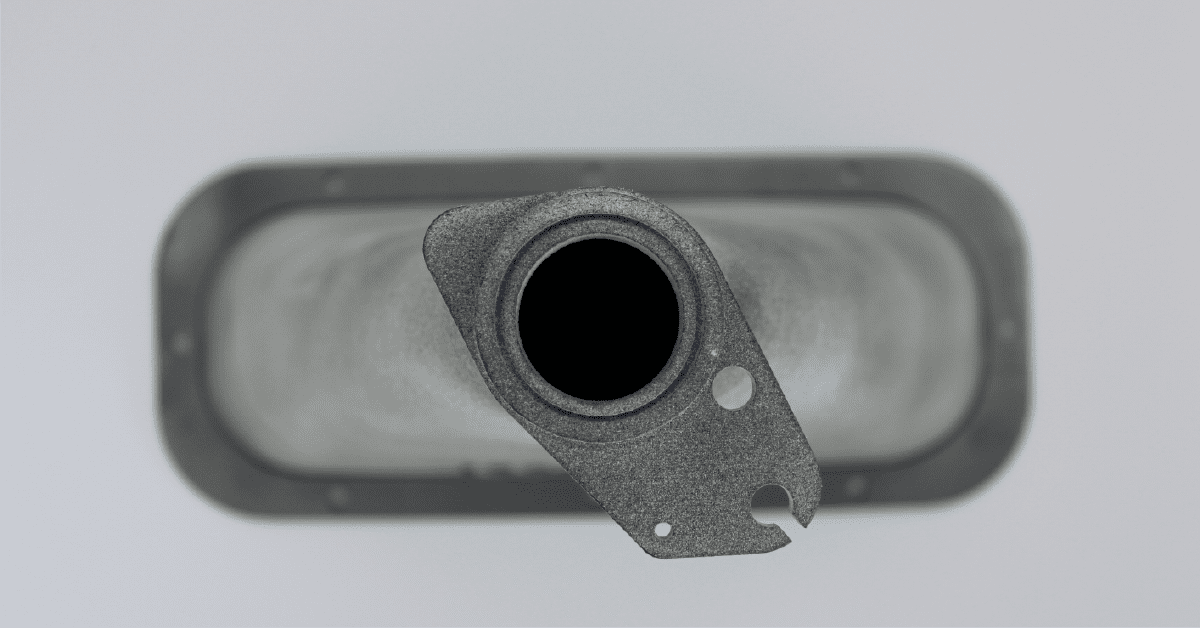

Automotive

Discover how 3D Printing is used in the Automotive Industry to develop products, parts and bring value to the end consumer.

Healthcare

Discover how 3D Printing is used in the Healthcare and Medical Industry to develop products and parts.

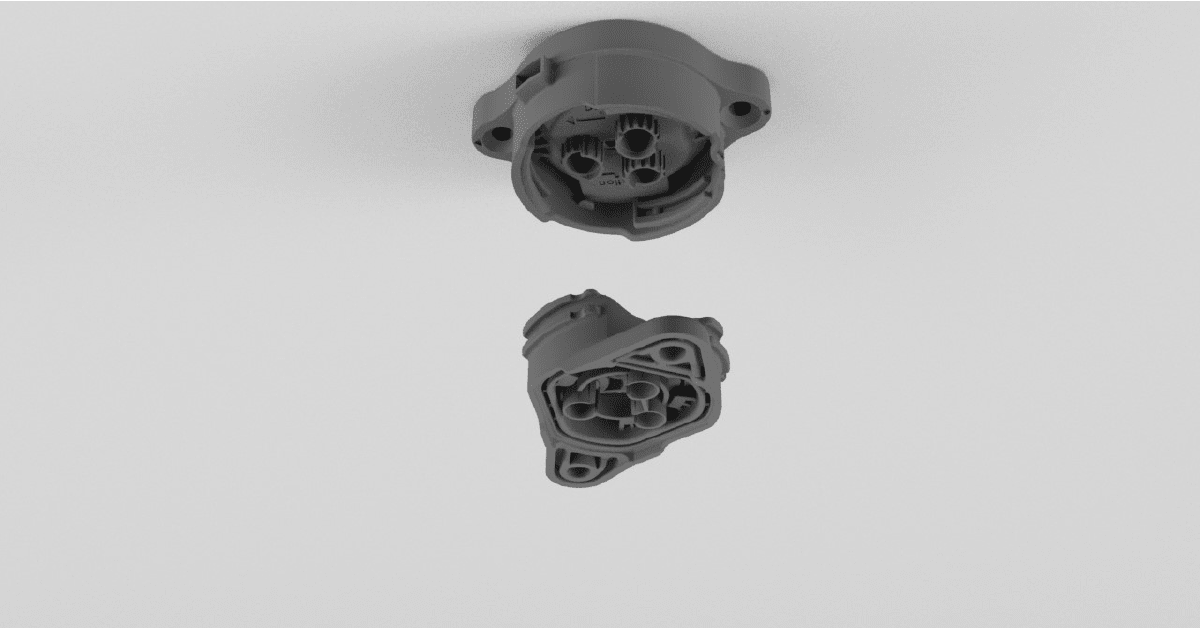

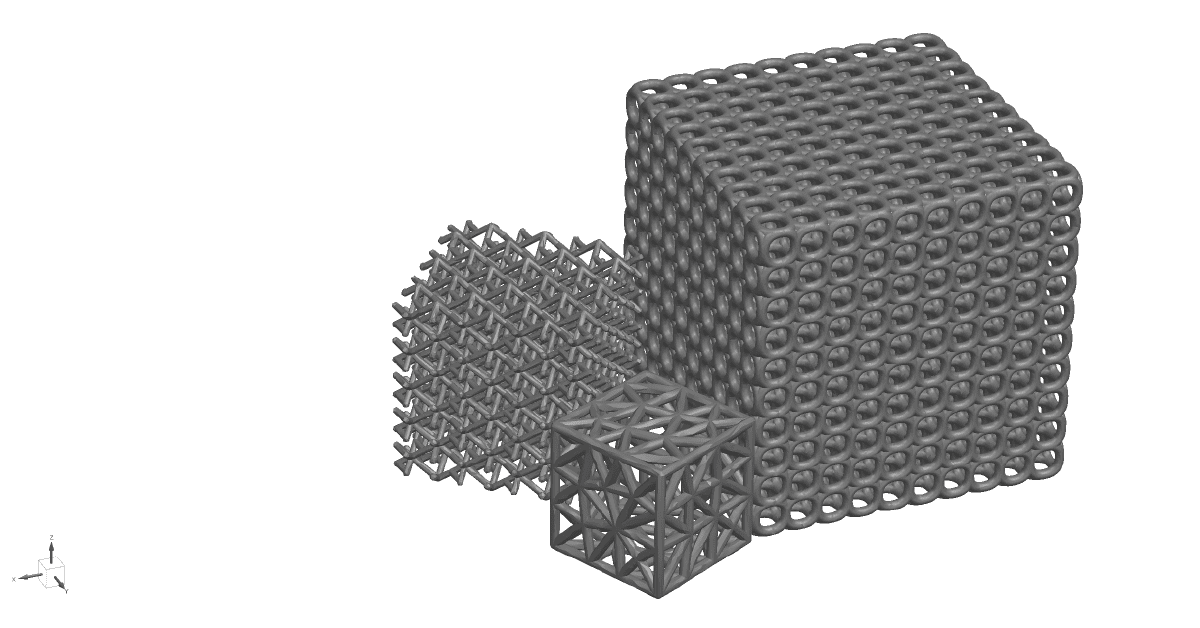

Chapter 04: Design for Additive Manufacturing (DfAM)

Introduction to Design Optimization

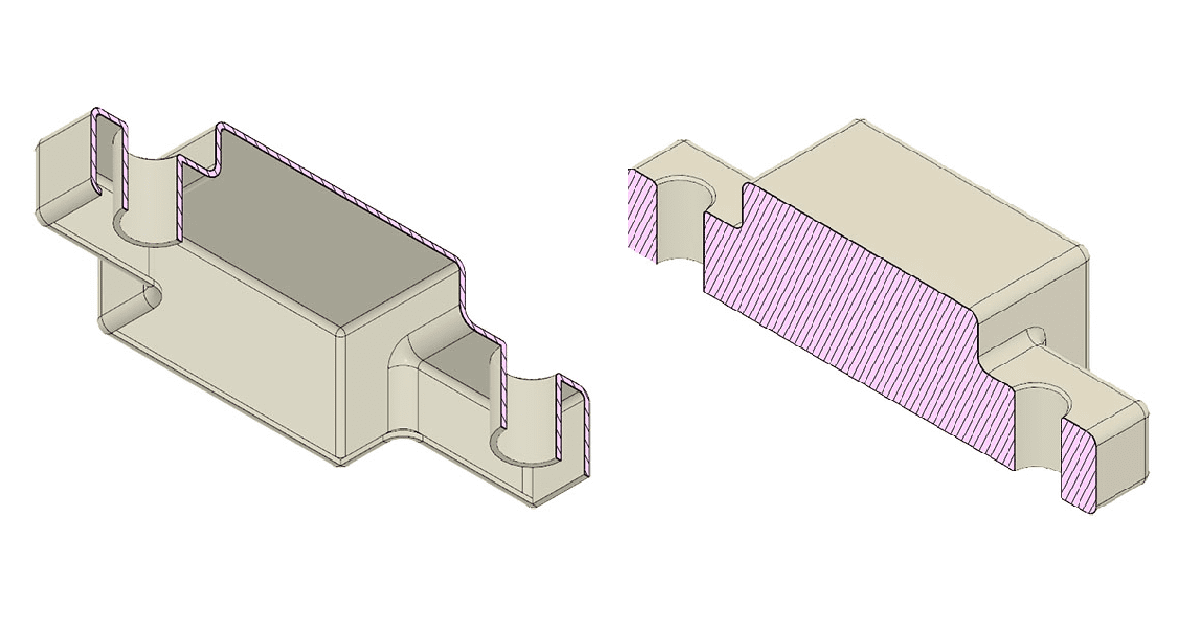

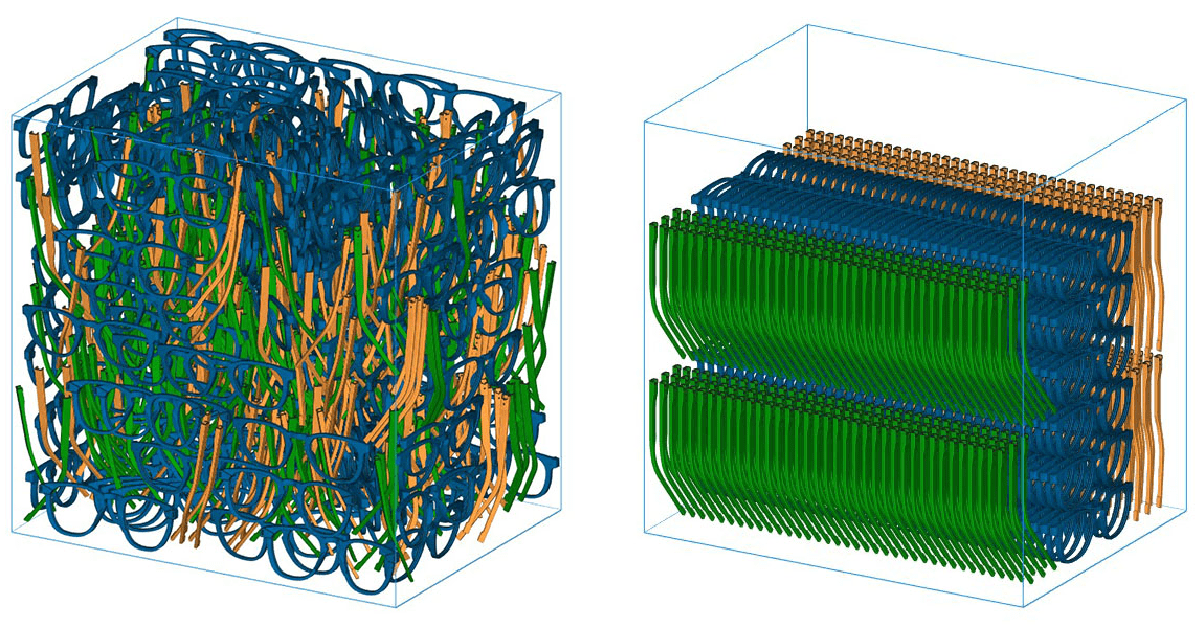

Design Optimization plays an important role. Through the use of techniques such as File Hollowing, Topology Optimization and Nesting Optimization, you can significantly reduce material usage.

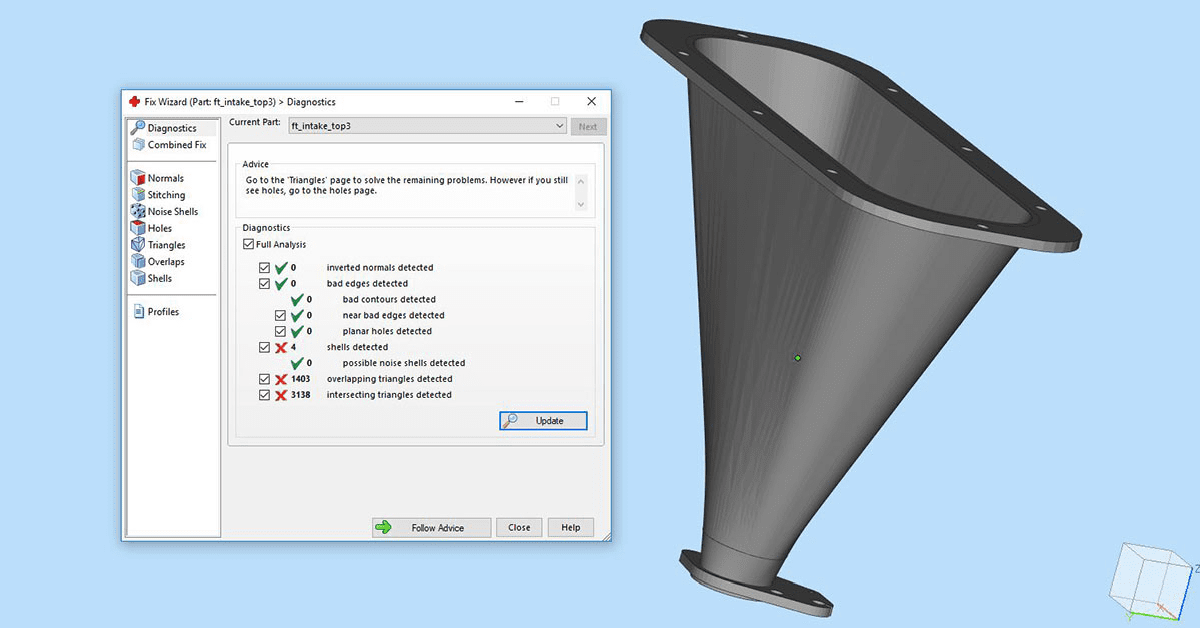

3D File

Optimization

This guide is your simple checklist that you can refer to, to ensure that you are sending us a fully optimized file for 3D Printing!

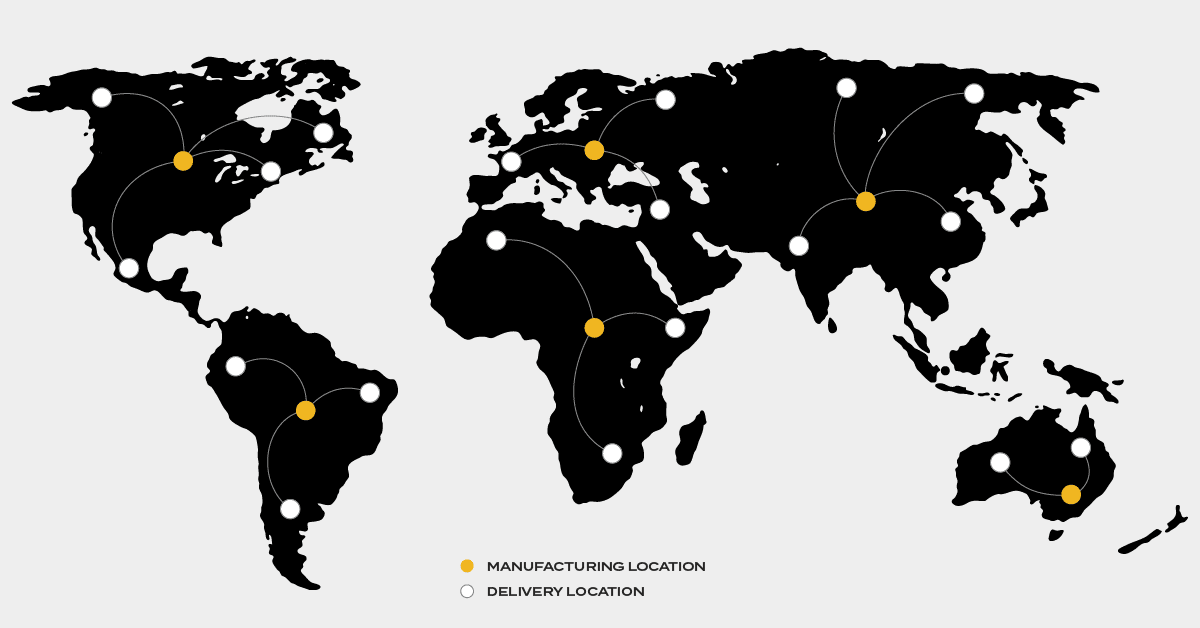

Chapter 05: Distributed Supply Chain & AM

Other Topics

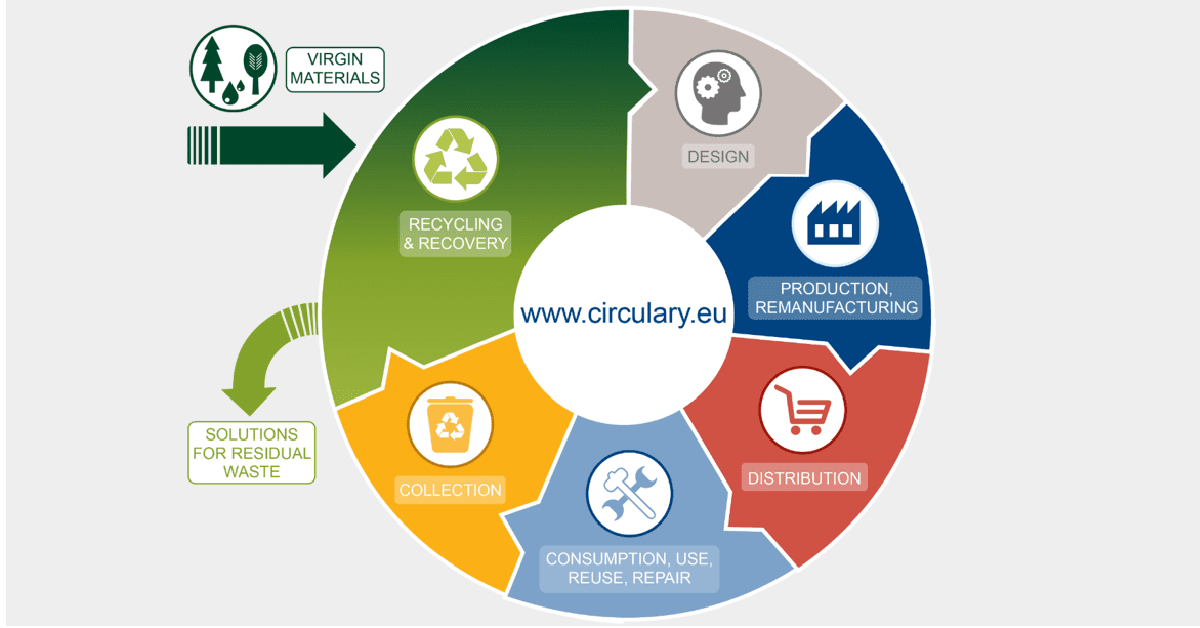

Transitioning from a Linear

to a Circular Economy

By being circular, the value of resources and materials are maximized in the life cycle of a product, they are then recovered and regenerated into new products and materials.