PA-11 Nylon, also known as polyamide 11, is a bioplastic, which is produced from the polymerization of 11-amino undecanoic acid. Usually, this material is derived from castor beans. There are numerous applications of PA-11 Nylon and it is used in various fields including Eyewear, Automotive, Textiles, Aerospace, Sports Equipment, Oil & Gas, and Electronics. This article highlights the technical properties of PA-11 Nylon and why the material is suitable for 3D Printing.

Chemically, this material is made from ricinoleic acid, which is composed of 90% castor oil. It has a very low density, water abortion, glass transition temperatures, and melting points. PA-11 Nylon has high dimensional stability, especially in the presence of moisture, this is due to a low amides’ concentration. In addition, the material has 1.8% weight variation and 0.5% length variation.

PA-11 Nylon provides higher chemical and heat resistance than PA-12 Nylon. The excellent resistance of the material is determined by the high elongation at break, which makes it ideal for testing and functional applications.

PA-11 Nylon enables the creation of 3D printed prosthetics and orthotics, and it has become a leading material for Medical 3D Printing due to its flexibility and structural properties. This material shows high potential to transform the medical industry and how medical professionals can utilize 3D printing technology to improve patient outcomes. Additionally, PA-11 provides a great benefit of lowering the harmful and/or negative ecological effects, which are most commonly associated with the petroleum-based plastics.

PA-11 Nylon provides higher chemical and heat resistance than PA-12 Nylon. The excellent resistance of the material is determined by the high elongation at break, which makes it ideal for testing and functional applications. Thanks to its great features, PA-11 Nylon is an ideal choice for many electrical and industrial applications. So much so, another significant property of PA-11 is that it is not hygroscopic. Hygroscopic refers to the absorption of moisture from the air and surroundings. Particulary in the electrical industry, water and moisture is a significant threat, therefore PA-11 is a strong choice for components and fittings. Low water absorption means post-processing is enhanced as parts can be finished using spray paints and color dyeing techniques.

- This thermoplastic material offers optimal mechanical properties and has excellent resistance to chemicals. It has high impact resistance as well as ductility for insoles, prostheses, sports goods, living hinges, snap fits, and much more.

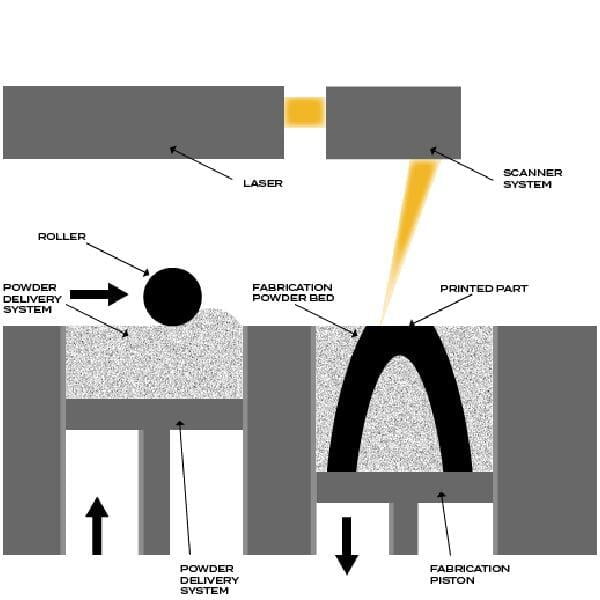

PA-11 is most commonly used in Selective Laser Sintering (SLS) Printers and Multi-Jet Fusion (MJF) Printers. SLS is considered the most suitable technology for PA-11 Nylon 3D printing. PA-11 Nylon is much more flexible than PA-12 since it has great all-around functional and mechanical properties ideal for prototyping. So, when printed using the SLS method, PA-11 is input as a powder in order to produce prints with state-of-the-art material properties, with raw surfaces that can be easily post-processed using various techniques such as tumbling and blasting.

Moreover, this thermoplastic material offers optimal mechanical properties and has excellent resistance to chemicals. It has high impact resistance as well as ductility for insoles, prostheses, sports goods, living hinges, snap fits, and much more. It is designed for the production of the functional and final parts across many industries. Furthermore, the material provides a great balance between performance, reliability, and re-usability.