03.02.2022

WAZP and Wematter agree to Collaboration

WAZP Smart Factory & Center of Excellence Facility

will test Wematter Gravity System

- Swedish 3D Printer Manufacturer, Wematter, and Global End-to-End Supply Chain for 3D Printing, WAZP, agreed to collaboration.

- The Wematter Gravity SLS 3D Printer which will be used in the testing and advancing WAZP’s specific material portfolio.

- WAZP announced in 2020 it's plans to expand it's operations in Kerry, Ireland. Read more.

Swedish 3D Printer Manufacturer, Wematter, and Global End-to-End Supply Chain for 3D Printing, WAZP, agreed to collaboration. WAZP ensures that its clients have access to the most advanced solutions and technologies that match their specific needs and goals in creating their products and components; the addition of the Wematter Gravity SLS 3D Printer which will be used in the testing and advancing of WAZP’s specific material portfolio, will fit well with the company’s efficient and sustainability-driven processes.

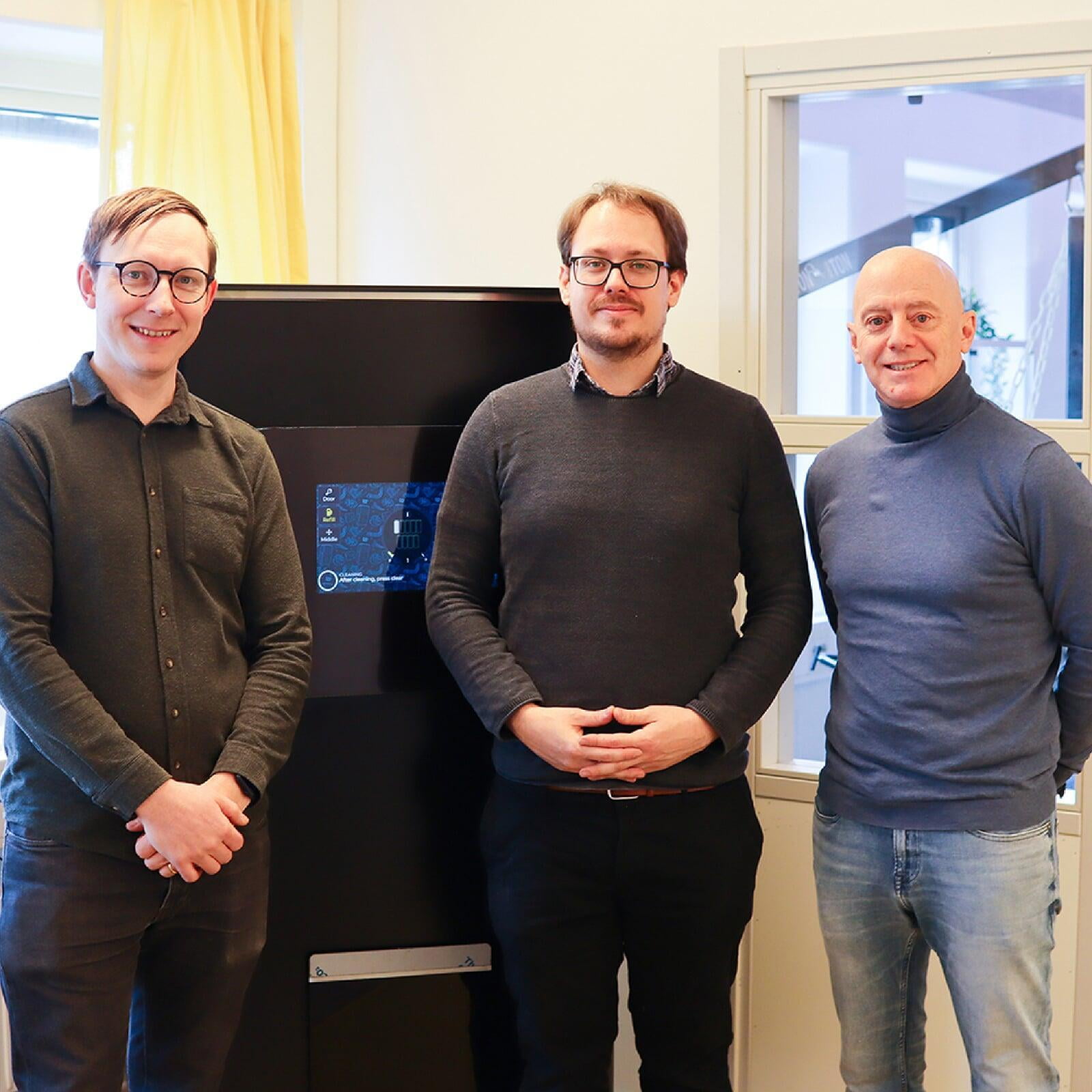

WAZP’s current expansion of global operations and the distributed manufacturing network, and the delivery of its on-demand manufacturing and direct-to-consumer fulfillment services played a role in the decision to begin this collaboration with Wematter. After the initial evaluation, Wematter technology shows defining factors that make Gravity SLS 3D Printer an obvious choice. Chief Supply Chain Officer, Sean Hassett, explains,

"We think that Wematter's system 'Gravity 3D Printer' can be placed almost anywhere since it's so compact as well as easy to use. Now that we've had a good introduction in Sweden, we're looking forward to getting started and seeing the printer in action."

Robert Kniola, Founder and CEO of Wematter, had this to say,

"WAZP is an experienced player in the additive manufacturing field with a large network of customers and partners that this collaboration can leverage. We both want AM to be more widespread through decentralization and WAZP has seen that our platform is more suitable and modern than the market has seen earlier. Wematter's Gravity as a key component is yet another proof of the value our solution delivers. In this case, our advances SLS technology will, among other things, contribute to the development of material studies."

For more information, contact:

Marketing Communications Specialist

Stephen Barry-Hannon

+353 (0)86 853 5908

About WAZP

WAZP offers clients the most advanced, sustainable, and flexible supply chain solution. By harnessing the power of Additive Manufacturing, WAZP inspires companies to produce quality products, closer to the point of need whilst achieving industry-defining pricing, increased design complexity, and efficient processes to support clients’ adoption of digital content manufacturing with ease and efficiency. Sustainability is built into the WAZP DNA by doing more with less, propelling operational excellence through a no-waste culture within the company. This goal is achieved by being creative, efficient, and resourceful. This means less waste and increased efficiency at all stages in the supply chain for clients. For more information about WAZP, please visit www.wazp.io

About Wematter

Swedish 3D printing company Wematter's pioneering solution gives hospitals, offices, and workshops access to a comprehensive system. For the first time, employees can easily print components themselves with the same strength and quality as traditional technology. Wematter’s proprietary end-to-end solution enables customers to accelerate product development and in-house volume production. At the same time, the system creates the conditions for increased flexibility, lower risk and reduced manufacturing and development costs. For more information about Wematter, please visit www.wematter3d.com