Design Optimization Techniques

You have designed your product and you are ready to start 3D Printing, but you receive your quote and realize that this print is more expensive than you thought. So, what do you do next?

Design Optimization plays an important role here. Through the use of techniques such as File Hollowing, Topology Optimization and Nesting Optimization, you can significantly reduce material usage which ultimately saves on costs.

Not only this, the reduction in material, allows designers the ability to significantly improve part aesthetics without compromising performance.

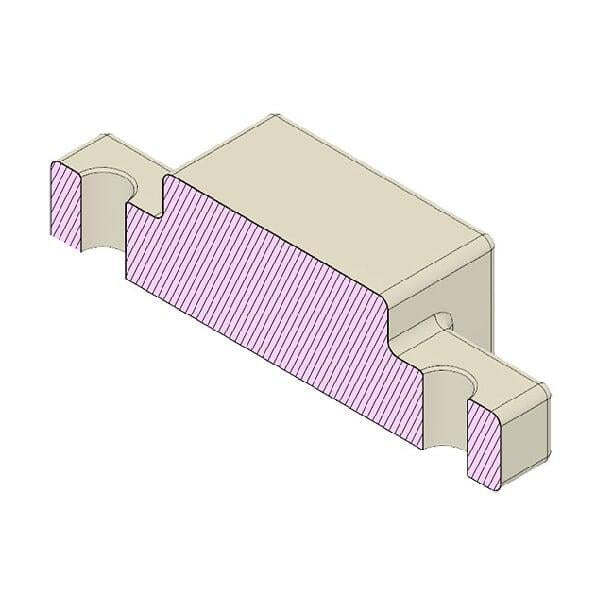

File Hollowing

Hollowing is a widely used optimization technique in powder-based printing such as Selective Laser Sintering and Multi-Jet Fusion.

Essentially Hollowing is used to create holes in solid 3D Models which enables the reduction in the overall volume of parts. These holes allow you to remove any excess powder during the post-processing stage

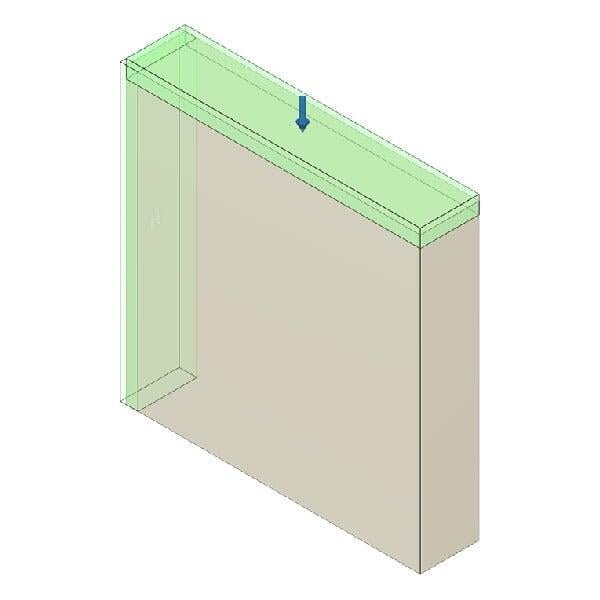

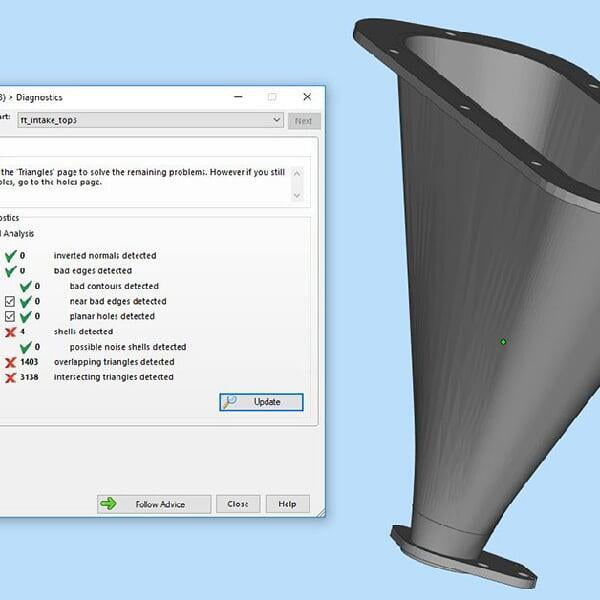

Topology Optimization

Topology Optimization is a technique that uses mathematical simulations to optimize the weight and geometry of parts. Both the indispensable and dispensable elements of the part are identified with the latter being removed from the design as they do not have any direct impact on performance.

Disover what happens to this part once the simulation has completed by clicking below!

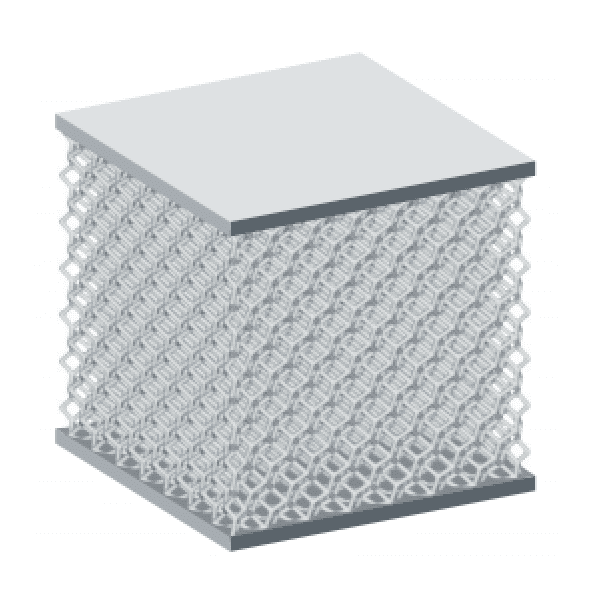

Lattice Structures

Lattices are used in 3D Printing to significantly reduce weight while maintaining the structural integrity of the part. It is quite similar to how topology works in terms of material removal but the key difference is that when using lattices, it can be applied at the start, during or after the initial design.

Download WAZP Lattice Catalog for more inspiration.